Policies have advocated the development of electric vehicles, which will further stimulate the booming development of battery materials.

- Electric vehicle brings an increasing demand to the modern battery industry.

Over the past five years, the global demand for electric vehicles has increased rapidly. In the next decade, we expect an exponential rise in EV sales. Because of elevated demand, auto manufacturers have been pressured to adjust their line-ups of models and associated supply chains to guarantee that they are the best set on this heightened demand outlook.

“According to Global EV Outlook 2022, Sales of electric vehicles doubled in 2021 from the previous year to a new record of 6.6 million. Back in 2012, just 120 000 electric cars were sold worldwide. In 2021, more than that many are sold each week. Nearly 10% of global car sales were electric in 2021, four times the market share in 2019. This brought the total number of electric cars on the world’s roads to about 16.5 million, triple the amount in 2018. Global sales of electric cars have kept rising strongly in 2022, with 2 million sold in the first quarter, up 75% from the same period in 2021.”

We note that the various strategies used by automakers and governments to rectify these issues have led to the politicization and localization of EV battery supply chains. The rise in EV demand has also spurred competition among EV and EV battery manufacturers to secure access to the critical raw materials used in LiBs, most notably lithium, cobalt, and nickel.

“Fitch Solutions analysis forecasted that global EV sales would reach over 26.7 million units in 2030, representing year-over-year growth of 379.0% in 2021. More importantly, in this series, the analysis forecasted that the annual global demand for EV batteries, in terms of total global capacity, would reach 1925 GWh by 2030, an increase of 688% from 244.7 GWh in 2021.”

- Promotes resource conservation by reusing materials.

The proliferation of electric vehicles worldwide signals significant strides toward cleaner transportation and a more environmentally sustainable society. Characterized by their eco-friendly aptitude, battery-powered EVs are celebrated for bringing remarkable environmental and social benefits, such as reducing carbon emissions, lessening air and noise pollution, and increasing energy efficiency.

On the other hand, the mounting demand for electric vehicles comes with looming concerns over the potential environmental burden of electric vehicle batteries. Particularly, large volumes of spent electric vehicle batteries without proper treatment will likely be disposed of as waste and become a significant environmental burden.

In addition, heavy reliance on virgin raw materials will hasten the depletion of natural resources such as cobalt and nickel, leading to roaring costs of electric vehicle battery production and consequently, hindering more widespread adoption of electric vehicles.

“According to market forecast suggests the volume of spent electric vehicle batteries is expected to increase significantly in the coming years and will escalate with the continuous rapid growth of the global electric vehicle market. On a yearly basis, in 2025, a survey forecast that 345,000 tons of end-of-life electric vehicle batteries would be generated globally, of which 80% would be generated in China.

China is the world’s largest new-energy vehicle market by sales volume since 2015 and is expecting even faster growth rates for the years to come. The China new-energy vehicle market is undoubtedly at the forefront of facing repurposing batteries.”

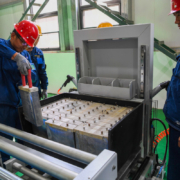

A practical solution addressing environmental and social issues in electric vehicle battery management is remanufacturing and reusing. Battery remanufacturing is an industrial process whereby the residual value of used products can be recaptured by restoring and reusing valuable working components, such as an uninterruptible power supply, repurposing battery energy storage system, etc.

This practical and logical approach enables used products to be restored and offered to consumers in like-new condition. Battery remanufacturing has been well-documented as an efficient and responsible end-of-life manufacturing strategy providing enormous economic, environmental, and social benefits.